"Global Executive Summary Packaging Robots Market: Size, Share, and Forecast

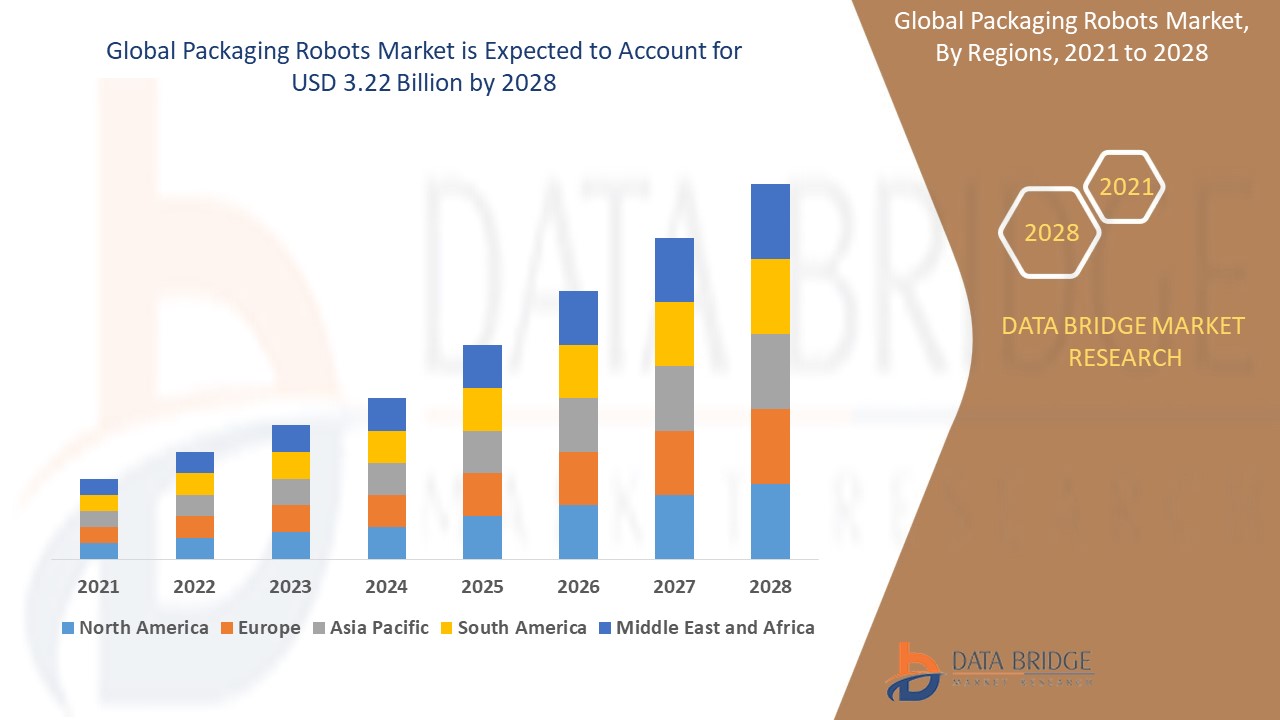

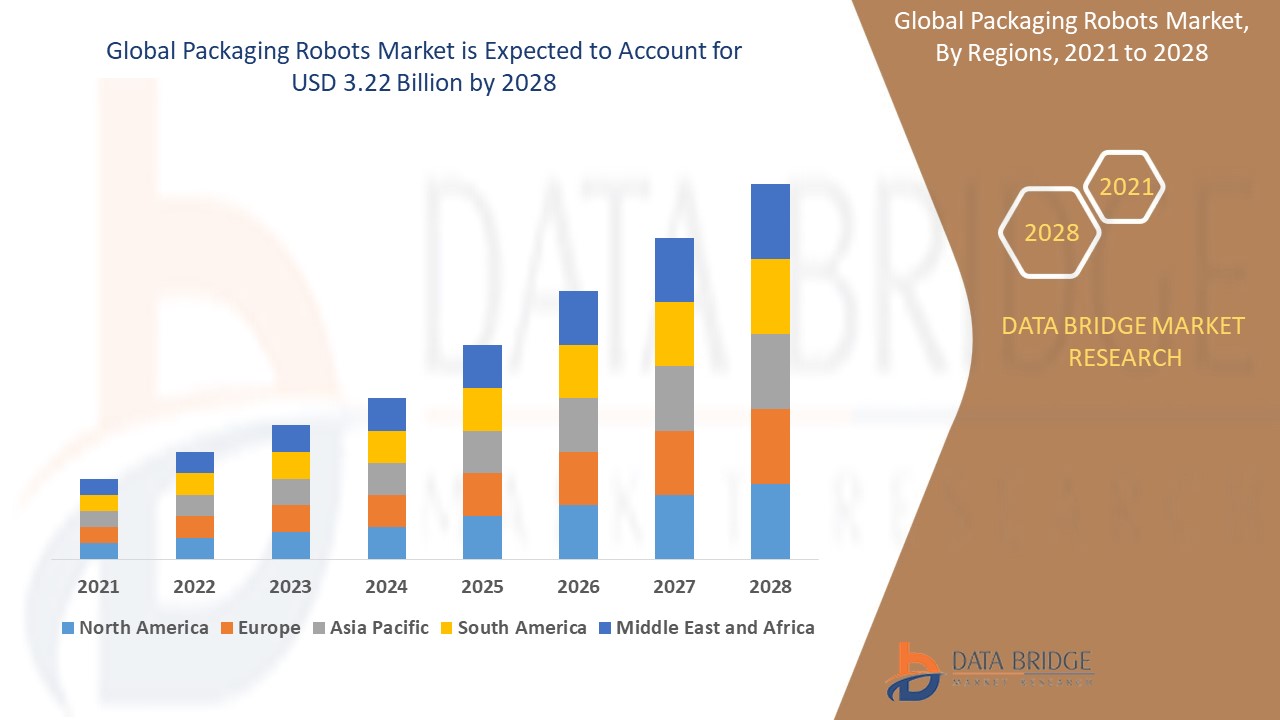

The packaging robots market size was valued at USD 2.14 billion in 2024 and is projected to reach USD 4.48 billion by 2032, with a CAGR of 9.70% during the forecast period of 2025 to 2032.

While preparing the first class Packaging Robots Market report, all the necessities and requirements of the businesses have been considered with which they can achieve successful business growth. All the data, statistics, facts and figures included in this report are very vital to the businesses when it comes to define the strategies about the production, Market, sales, promotion, advertising and distribution of the products and services. The large-scale Packaging Robots Market analysis report also endows with an insightful overview of product specification, technology, product type and production analysis by taking into account most important factors such as revenue, cost, and gross margin.

Packaging Robots Market research report performs an estimation of the growth rate and the market value based on market dynamics and growth inducing factors. A variety of steps are employed while generating this report and the inputs from a specialized team of researchers, analysts and forecasters have been utilized here. Besides, the report is wonderfully characterized using several charts, graphs and tables depending on the extent of data and information involved. Clients can divulge best opportunities to be successful in the Packaging Robots Market industry with an excellent practice models and method of research used in the consistent Packaging Robots Market report.

Stay ahead with crucial trends and expert analysis in the latest Packaging Robots Market report.Download now:

**https://www.databridgemarketresearch.com/reports/global-packaging-robots-market**

Packaging Robots Industry Overview

The packaging robots market is poised for substantial growth in the coming years, driven by a multitude of factors including increasing automation in industries, rising demand for efficient packaging solutions, and the need for enhanced productivity and operational efficiency. One key trend shaping the market is the emphasis on payload capacity segmentation, catering to the diverse needs of different industries. Low payload capacity robots are gaining traction for their cost-effectiveness and suitability for small to medium-sized operations, while high payload capacity robots are finding applications in heavy-duty industries like automotive and electronics. This segmentation strategy allows companies to offer tailored solutions to meet specific payload requirements, contributing to market expansion.

In terms of application segmentation, the packaging robots market showcases a diverse range of uses, each offering unique benefits to businesses. Picking robots are crucial in e-commerce fulfillment centers for efficient item selection, while packing robots streamline the packaging process by accurately placing products into containers. Palletizing robots automate the stacking of products onto pallets, optimizing warehouse operations, and case/tray handling robots facilitate container movement within production lines. This segmentation highlights the versatility of packaging robots in addressing various operational needs across different industries, indicating a broad scope for market growth and innovation.

The end-user segmentation in the packaging robots market underscores the significant role played by industries such as food and beverage, pharmaceuticals, consumer goods, logistics, automotive, and others in driving market demand. The dominance of the food and beverage sector can be attributed to the increasing focus on automated packaging solutions to ensure food safety and hygiene standards are met. The pharmaceutical industry relies on packaging robots for precise handling of medications and regulatory compliance, while consumer goods companies leverage robots for efficient product packaging. This segmentation reflects the diverse applications of packaging robots across industries and underscores the market's potential for expansion and technological advancement in catering to specific industry requirements.

In conclusion, the packaging robots market presents substantial opportunities for growth and innovation fueled by increasing automation trends, industry-specific demands, and the evolution of advanced robotic technologies. Key market players such as ABB, FANUC Corporation, Yaskawa America, Inc., and others are strategically positioned to capitalize on these opportunities through product innovation, strategic partnerships, and expansions. By focusing on segmented strategies based on payload capacity, applications, and end-users, companies can align their offerings with specific market needs and drive sustained growth in the competitive landscape of the packaging robots market.The packaging robots market is experiencing a significant surge in growth, driven by the increasing adoption of automation across various industries. One of the key drivers for this growth is the demand for efficient and cost-effective packaging solutions that can enhance operational efficiency and productivity. As companies across different sectors strive to optimize their processes, the need for advanced automation tools like packaging robots becomes imperative. This trend is further amplified by the focus on payload capacity segmentation, with companies offering robots tailored to specific needs based on low, medium, or high payload capabilities. This segmentation strategy allows for a more targeted approach in addressing the diverse requirements of different industries, ultimately contributing to the expansion of the market.

Furthermore, the segmentation of the packaging robots market based on applications highlights the versatility and adaptability of these robots in meeting various operational demands. From picking and packing to palletizing and case handling, these robots offer specific functionalities that cater to different aspects of the packaging process. For instance, picking robots are essential in e-commerce fulfillment centers where efficient item selection is crucial, while palletizing robots streamline warehouse operations by automating the stacking of products onto pallets. This application segmentation underscores the multifaceted role of packaging robots in enhancing workflows and improving overall efficiency across industries.